Introduction: This article is about the design of the 600 tons of crushed stone production line, how to choose the equipment and the price of the equipment. The case in this article has been officially put into operation, the working performance of the crushing equipment is stable, and the output is guaranteed at 500-600 tons per hour. The raw materials of the mine are: limestone, strength: about 100Mpa, obvious texture (shale), silicon and calcium content is about 20 ~ 25%; most of the materials that enter the jaw crusher after blasting are less than 200mm, about 30%, 500mm ~ 700mm accounts for about 20%, and the remaining fines are more.

1. Description of equipment selection for production line:

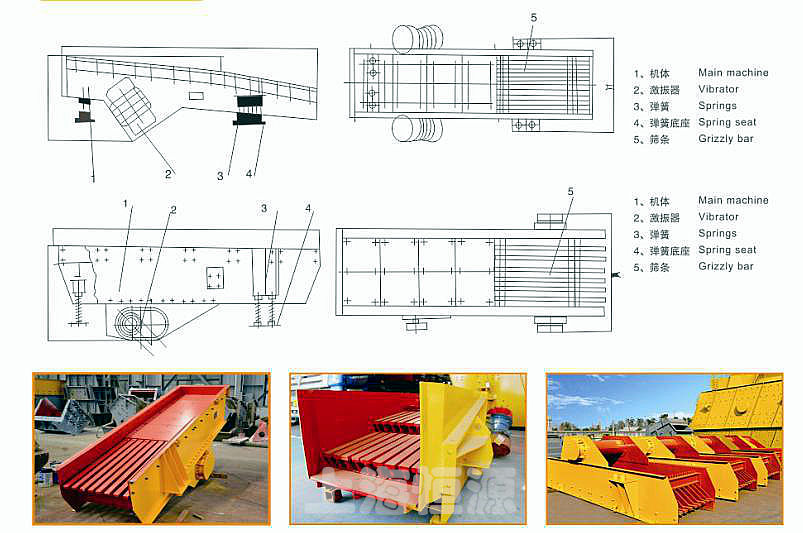

1. Inverter bar feeder

Adopt ZSW600 * 130 frequency conversion vibration feeder to meet 700t / h feeding amount;

The screen strip spacing of the feeder is 60mm, the screen strip is a two-layer ladder, and the length of the screen strip accounts for not less than 3/5 of the total length of the feeder;

The sieves of the sieve of the feeder enter the desilting sieve for desilting.

Advantages of equipment:

Strong processing ability

The equipment adopts double eccentric shaft vibration exciter with high vibration frequency, which has stable performance and strong excitation force. With two-stage stepped grate bar, the feeding is faster and smoother, which greatly improves the feeding capacity of the equipment.

Feeding can be adjusted

The equipment is driven by a motor and a pulley, and can be equipped with a variable frequency controller to control and adjust the feeding amount of the equipment, which is accurate and regulated to ensure the safe and stable operation of the subsequent equipment.

Low maintenance cost

The equipment has compact structure and small installation size. The main force parts of the feed box and the material of the protective plate are upgraded, which improves the wear of the tank and reduces the maintenance. The caster bar is made of high-manganese steel, which has stronger structural bearing capacity and longer life.

Optimize production line process

The equipment is equipped with feeding grate bars, which can pre-screen the feeding materials. At the same time, it can adjust the feeding grate bar gap according to the production line process requirements, optimize the production line process, and improve production efficiency.

2.PV European version jaw breaking

Adopt PV912 European version V-shaped jaw crusher, equipped with 160KW motor;

The feed size is 700mm ~ 60mm, of which about 30% is less than 200mm; the output is 200mm (more than 200mm but the maximum 250mm does not exceed 10% of the total). Under this condition, the feed of PV912 jaw breaking reaches 500t / h;

Advantages of equipment:

Structural stability and reliability

The bearing seat adopts an integral cast steel structure to avoid unnecessary burden on the frame caused by the two-piece bearing chamber and improve the stability of the whole machine structure. In addition, the heavy eccentric shaft is processed by forging billet, which makes the PV series jaw crusher have extraordinary reliability.

European version is convenient for cavity cleaning

Equipped with a combined gas station to ensure that the machine lubrication system supplies oil to the parts that need to be lubricated by the machine, providing protection for the safe operation of the machine. At the same time, if the crusher is stopped under load, the cavity cleaning system can quickly clean the crushing cavity, greatly reducing the downtime.

V-shaped structure toothed guard plate technology advanced and long service life

The design of "V" type crushing cavity and toothed guard plate is more reasonable, ensuring the consistency of the actual feeding size and the theoretical feeding size, effectively increasing the crushing area, and the material will not block in the crushing cavity, so that the crushing rate and output Maximize and improve the utilization of the jaw plate.

Quick adjustment of wedge device

Adopting the wedge block discharge opening adjustment system, so that the machine can adjust the discharge opening to a predetermined value within a few minutes even under idling conditions. With the coordination of the adjustment system, it can achieve automation, which is better than the old-style gasket discharge opening. The adjustment system is simpler, safer and faster.

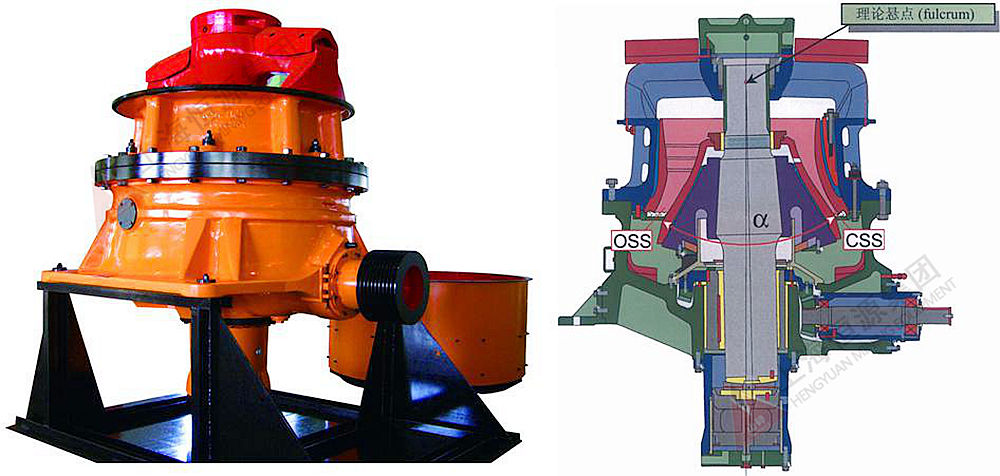

3. Medium broken (thick cone)

Using HD44-S single cylinder hydraulic cone crusher, equipped with 250KW motor;

The feed particle size is ≤200mm, the discharge particle size is 80mm (80mm ~ 100mm does not exceed 10%), and the return material is not considered. Under this condition, the theoretical maximum feed rate of DS44 single-cylinder cone breaking reaches 500t / h;

Advantages of equipment:

High production efficiency and strong carrying capacity

The single-cylinder cone crusher realizes the "theoretical suspension point" of the cone crusher, which greatly optimizes the stress structure of the main shaft. The rotor of the traditional cone crusher is only a cantilever structure; the rotor of the single-cylinder cone crusher, due to the actualization of the theoretical suspension point, makes the crushing force significantly enhanced.

Compared with the traditional spring cone and multi-cylinder cone, the crushing efficiency of the single-cylinder cone crusher is about 15% higher.

Production adjustment is extremely convenient

The single-cylinder cone crusher adopts the bottom hydraulic cylinder structure and discards any external components. The bottom hydraulic cylinder structure makes it easy to adjust the discharge opening of the cone break. Even in the working running state, the discharge port can be quickly adjusted through the control button. The size of the discharge port can also be set automatically through the LCD control panel and input mode.

Fully automatic control of the production process

The automatic control system provides manual operation, constant discharge port control, constant power control and other operation modes for selection;

Easy maintenance and low operating cost

The equipment structure is simple, and all maintenance work can be completed after removing the upper frame, which not only makes inspection and maintenance more convenient, but also lowers maintenance costs.

Multi-cavity type adapts to various process requirements

There are a variety of standard crushing cavity types to choose from, and the eccentricity can also be flexibly changed. According to different production processes, it can be equipped with a suitable crushing cavity type and eccentricity to meet the crushing requirements.

4. Fine break (fine cone):

Using HD53-C single cylinder hydraulic cone crusher, equipped with 315KW motor;

The feeding particle size is 80mm ~ 15mm (80mm ~ 100mm does not exceed 10%); under CSS = 32mm, the theoretical maximum feeding amount of HD53-C single-cylinder hydraulic cone crusher reaches 500t / h;

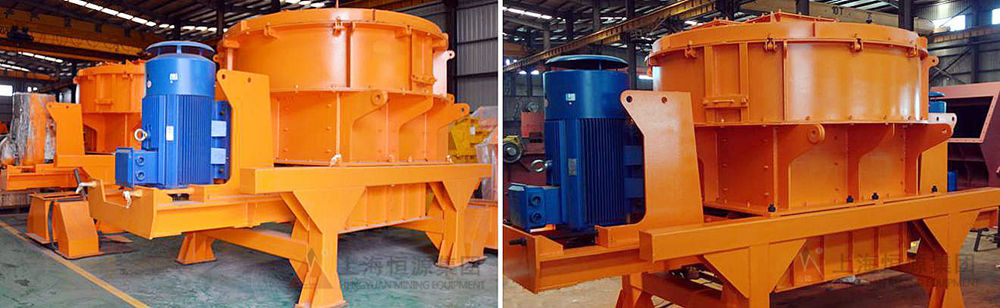

5. Frequency conversion shaping machine:

Using two HB1200 frequency conversion shaping machines, each shaping machine is equipped with two 185KW motors;

Two shaping machines, the feed volume is 400t / h + the return feed (the output volume is 400t / h); the feed particle size is 30mm ~ 10mm; the discharge particle size is ≤25mm, greater than 25mm and no more than 10%

After impact shaping, the ratio of 0 ~ 5mm, 5mm ~ 10mm, 10mm ~ 25mm is basically linearly distributed, and the actual ratio can be adjusted by the inverter.

Advantages of equipment:

Excellent integer function

High speed impact characteristics, in the process of vortex crushing, the stone material obtains multi-angle impact crushing, thereby obtaining very excellent shaping effect;

Precision casting of wear-resistant parts, long service life

Wear-resistant parts, long service life.

Low noise, low vibration, less dust, meet environmental protection requirements

In the manufacturing process of the impact crusher rotor, high-speed dynamic balancing equipment is used to modify the rotor dynamic balance to ensure the stability and reliability of the rotor during high-speed operation, and the vibration amplitude is very slight.

Air circulation devices are installed on both sides of the material inlet, and the wind generated by the rotation of the rotor circulates in the circulation device to reduce the amount of dust discharged to the outside. The rotor that rotates at high speed adjusts the balance, thereby achieving low noise and low vibration.

Hundreds of application cases

The HB series impact shaper produced by Shanghai Hengyuan, with a large number of cone crushers, has been widely used. After years of experience accumulation and technical improvement, it has reached a very stable and reliable operating state;

Simple maintenance

The machine can be opened automatically or hydraulically, making it easier to replace wearing parts.

6. Frequency conversion sand making machine:

Using two HX1200 frequency conversion sand making machines, each shaping machine is equipped with two 185KW motors;

Two sand making machines, the feed volume is 200t / h + the return material (the discharge volume is 200t / h); the feed particle size is two kinds: 0 ~ 10mm and 0 ~ 15mm (from the waste water washing)

Finished material of sand making machine: medium sand (fineness modulus 2.6 ~ 3.0) and powder below 0.075, the ratio of sand and powder can be adjusted by frequency conversion adjustment;

7. Suspension feeder:

All adopt frequency conversion control, and the hopper is equipped with wear-resistant plates.

Advantages of hanging feeder equipment:

1. Small size, light weight and simple structure;

2. Convenient installation, operation and maintenance, low energy consumption;

3. High transmission efficiency;

4. Low noise, conducive to improving working environment;

5. Low power consumption and high power factor;

6. The equipment works in a state far beyond resonance, so the amplitude is stable, the operation is reliable, and it has strong adaptability to various materials.

8. Vibrating screen:

Adopt new YKA round vibrating screen;

A curved screen is adopted, and tensioning plate devices on both sides are used;

Configure hydraulic wrench or pneumatic wrench;

Advantages of equipment:

Strong excitation force and easy to adjust

The YAK3072 vibrating screen used in this project adopts a strong double-vibrator structure, which can obtain a strong exciting force. By adjusting the eccentric block, the amplitude and exciting force of the vibrating screen can be quickly adjusted.

Curved screen, screen surface without pressure bar

The YKA series vibrating screen optimizes the structure of the screen box. The screen is fixed by the tensioning plates on both sides. The screen surface is not pressed, and the screen surface is curved. Therefore, the materials can be quickly dispersed on the curved screen without obstruction, and a high-efficiency screening effect can be obtained;

The screen surface has no pressing strips, which makes the replacement of the screen very convenient, without the need for personnel to climb into the screen box to disassemble the bolts, and replace the screen quickly;

Universal joint coupling

The use of a universal joint coupling makes the bearing of the vibrating screen greatly optimized, and the bearing has a long service life and is difficult to damage.

2. Flow chart of 600 tons crushed stone production line

Third, the production line equipment selection list and price

|

Serial number |

Device name |

Equipment model |

Quantity |

Power (kw) |

Dimensions (m) |

Weight (t) |

|

1 |

Vibration feeder |

ZSW600*130 |

1 |

37 |

6.08*2.58*2.08 |

7.8 |

|

2 |

European version jaw crusher |

PV912 |

1 |

160 |

3.33*3.18*3.02 |

39.3 |

|

3 |

Double vibration circular vibrating screen |

2YKA2475 |

1 |

2*22 |

8.67*4.65*1.7 |

15.2 |

|

4 |

Single cylinder cone crusher |

HD44(S) |

1 |

250 |

4.83*2.28*3.01 |

18.5 |

|

5 |

Single cylinder cone crusher |

HD53(C) |

1 |

315 |

4.75*2.6*3.61 |

32 |

|

6 |

Double vibration circular vibrating screen |

2YKA2475 |

2 |

2*2*22 |

8.67*4.65*1.7 |

2*15.2 |

|

7 |

Impact shaping machine |

HB-1200 |

2 |

2*2*185 |

5.71*2.88*3.15 |

2*18.3 |

|

8 |

Double vibration circular vibrating screen |

3YKA2475 |

2 |

2*2*22 |

8.67*4.65*2.16 |

2*18.6 |

|

9 |

Impact sand making machine |

HX-1200 |

2 |

2*2*185 |

5.71*2.88*3.15 |

2*18.3 |

|

10 |

Double vibration circular vibrating screen |

2YKA2475 |

2 |

2*2*22 |

8.67*4.65*1.7 |

2*15.2 |

|

11 |

Hanging feeder |

GZG1253 |

12 |

12*2*2.2 |

2.2*1.7*1.6 |

12*1.1 |

|

12 |

Centralized control system |

Using Siemens PLC control system, integrated control of all power devices of the production line. With automatic and manual dual-mode control. Configuration parameters adjustment touch screen, production line analog display. Possess remote communication capability, current value setting, monitoring and storage capabilities. The quotation does not include the electronic control of third-party equipment (powder selection, dust collection, roller press). Supplement the quotation after obtaining the third-party electronic control requirements. The non-standard steel structure of the production line includes "equipment foundation, access hopper, walkway escalator". All steel structures adopt sandblasting surface treatment and factory pre-installation. All steel structures are sprayed with one-time primer and two-time topcoat. Calculated temporarily based on 200 tons, more reimbursement less. |

|

13 |

Non-standard steel structure |

1. The price of crushed stone production line equipment can be obtained by consulting our customer service. Feeder and impact breaker are equipped with frequency conversion motor;

2. Belt conveyor, concrete foundation, wire and cable are not included in the quotation;

3. Payment method: 20% of the total contract amount is used as the equipment reservation deposit, 10% of the contract amount is the prepayment, and 70% of the total contract amount is paid before delivery;

4. Delivery cycle: after receiving the prepayment, the supplier's factory will deliver within 60 working days;

Fourth, the control system, non-standard steel structure program description

1. Control system:

All feeders and impact breakers use a frequency conversion system to adjust the feeding amount and speed;

The production line adopts Siemens PLC control system, integrated control of all power devices (main motor) of the production line;

The control system has two control modes, "automatic and manual", which can be switched;

Automatic control mode: The start and stop of the production line are automatically executed in the set order, and the order can be edited. In the automatic operation mode, before the production line is started, the warning light + loudspeaker is used for early warning;

Manual control mode: You can manually control the operation and stop of any device randomly;

Each unit on the production line is equipped with an emergency stop switch, which is convenient for handling emergency accidents on site;

The console is embedded with a touch screen display. Through the touch screen display, various parameter settings can be adjusted, storage records can be obtained, and the cause of the fault can be displayed;

A large screen display is arranged above the console, and the animation simulates the running state of the production line, and displays the actual operating parameters (current, temperature, etc.), and the abnormal state is displayed and alarmed in the simulation diagram;

The control system has remote communication capabilities.

2. Non-standard steel structure parts:

Shanghai Hengyuan Metallurgical Equipment Co., Ltd. completed the design of steel structure drawings and completed the manufacture of steel structure parts;

Sandblasting on the surface of the steel structure, one-time primer and two-time topcoat to ensure long-term use of the steel structure;

Our company will complete the pre-installation work of steel structure parts and equipment host to ensure the smooth installation on site;

Due to the longer design time of the overall steel structure of the production line, the total steel structure is currently estimated to be 200 tons. It is recommended that after the implementation of the project, according to the actual weight and the unit price of the contract, more refunds will be made.

Fifth, third-party equipment description of crushed stone production line

The 600TPH sand and gravel production line integrates crushing equipment, conveying equipment, powder selection equipment, dust collection equipment, and control equipment. It is a comprehensive project. For third-party equipment, such as conveying equipment, powder selection equipment, dust collection equipment, and roller press equipment, the equipment supplier reserves the position of the third-party equipment and reserves the control during the design of the floor plan The port of the system. After the user selects a third-party manufacturer, the third-party manufacturer provides the supplier with the basic product drawings and control requirements. The supplier is responsible for completing the overall process design of the third-party equipment.

6. Description of the basic structure of the crushed stone production line

In the actual design and manufacturing process of the production line, the following requirements should be fully followed:

1. Under the main equipment, design a large enough maintenance space, easy to install the dust collection device, and facilitate the maintenance and inspection of equipment personnel;

2. The discharge hopper adopts the material slope anti-wear design. The material hopper that cannot be designed with the material slope is equipped with wear-resistant parts to improve the wear cycle;

3. The conveying capacity of the waste belt under the feeder needs to be enlarged, and there is too much waste in the raw material. Consider 200 ~ 300TPH. The waste sieve fully considers the screening capacity;

4. For large belts and long belts, the inclination angle should be as much as 20 degrees to reduce the floor area;

5. Consider the position of the atomizing device at the inlet. Our company will reserve the position of the atomizing device in the design of the feed inlet according to the requirements of the third party selected by your company;

The above crushed stone production line case was designed by Shanghai Hengyuan Metallurgical Equipment Co., Ltd. and equipment selection and quotation. If you want to know how much the complete set of crushed stone production line with an annual output of 1200 tons, you can send us an email or leave a message on the website.

Sales Phone: + 86-21-33781259

Email: info@shhyyj.com