On June 20, 2020, the iron ore production line in Inner Mongolia sent a report on the field application and operation status of the equipment. The single-cylinder cone crusher in this case was produced by the company. The feedback of the equipment in the field application is good and the production and operation are all good. normal.

This single-cylinder hydraulic cone crusher model is HD-53, motor power is 315kw, discharge port is 19mm, crushed iron ore material is crushed, and the finished material of about 12mm is sieved through a vibrating screen, and the output is 180 tons/hour. about. The cone crusher is equipped with a Siemens LCD control cabinet to accurately feedback the operating status of the equipment; the main engine lubricating oil system uses air-cooled hydraulic thin oil station to ensure the reliable operation of the machine for a long time.

Let's take a look at the photos of the operation status of the field equipment and machines

Figure 1: Single cylinder cone crusher

Figure 2: Iron ore conveying hopper device

Figure 3: Hydraulic thin oil station

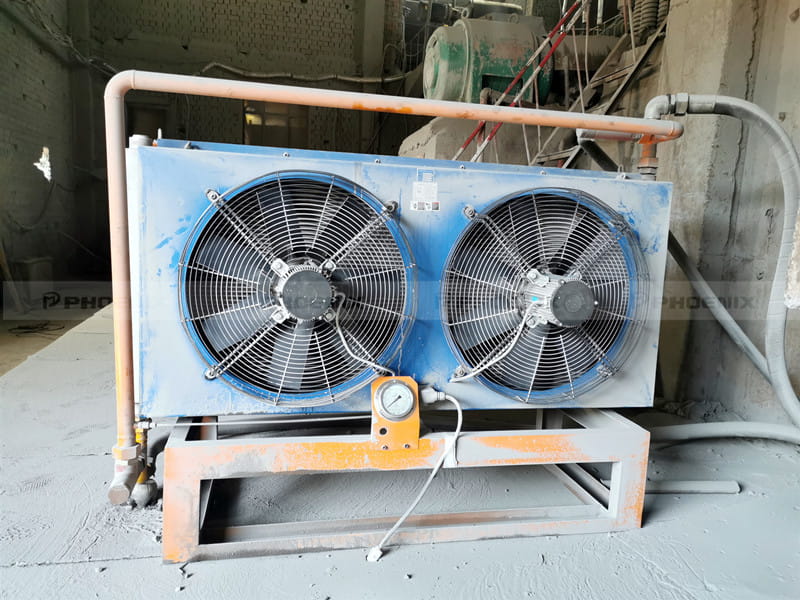

Figure 4: Air cooling device of hydraulic thin oil station

Figure 5: Siemens LCD electrical control cabinet

Figure 6: Finished product pile

The above are the photos and videos of the equipment working site. Here is a brief introduction to the advantages and characteristics of single-cylinder cone crusher:

Performance advantages of single-cylinder cone crusher

The company's new high-capacity HD series single-cylinder hydraulic cone crusher is widely used in construction, mining, building materials, metallurgy, water conservancy and other fields due to its high performance, high efficiency, high reliability, and high cost performance. The equipment is designed with the principle of constant crushing cavity, which changes the concept of fine crushing and crushing, and adopts advanced lamination crushing technology. The balanced crushing force around the crushing cavity makes the crushed particles fine and even. High degree of automation, proper eccentricity, through the discharge port and automatic and uniform feeding settings, the raw materials are in a specially designed crushing cavity, and they are layered compressed and crushed.

Single cylinder cone crusher features

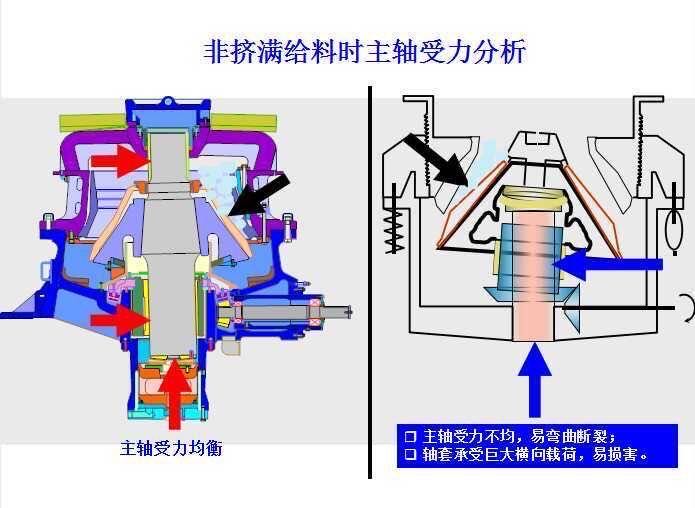

1. Both ends of the upper frame support the arm frame structure, so that the main shaft is evenly stressed. The upper boom guard plate and boom are made of high alloy wear-resistant materials, which effectively protect the boom from being worn.

Figure 7: Spindle force analysis

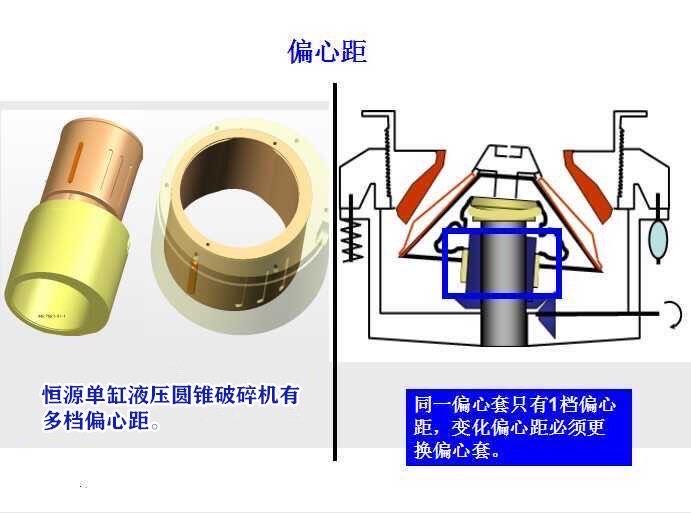

2. Different eccentricity can be selected according to the compressive strength of the crushed material, and the same eccentric sleeve of the same product multi-cylinder cone crusher has only one eccentricity. If the eccentricity changes, the eccentricity must be replaced.

Figure 8: Eccentricity

3. The lower frame is designed as a three-rib integral support structure, the rib arm guard plate can be replaced, and the side wall of the lower frame body has an observation door to monitor the wear of the guard plate at any time.

4. The angle of the moving vertebral body is small, the discharge is smooth, and the throughput is higher.

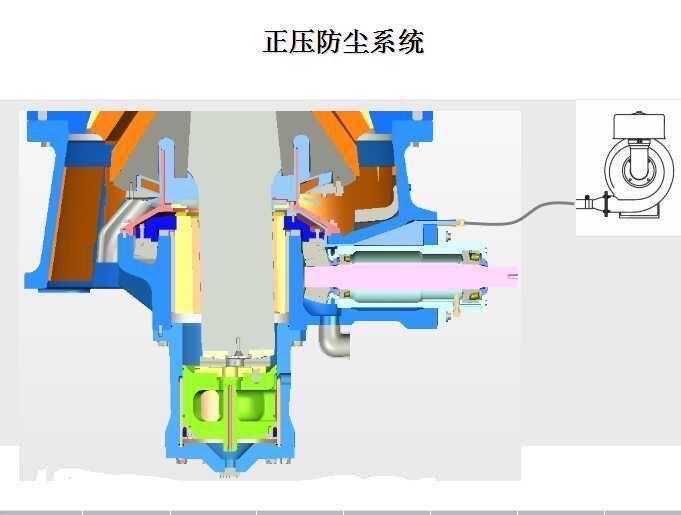

5. Positive pressure dustproof device The internal air pressure of the crusher is greater than the external air pressure, which effectively prevents dust from entering the core area of the crusher.

Figure 9: Positive pressure dust control system

6. Equipped with Siemens intelligent operating system electric control cabinet, which can monitor various parameters of equipment operation at any time, and can automatically complete the compensation function of worn parts; and adjust the size of the discharge port through the operation of the LCD screen.

Figure 10: Automation control system

7. The shock absorber steel frame of the cone crusher is equipped with a compression rubber pad, which can reduce the load on the foundation when the crusher is running.

8. Sturdy equipment structure and advanced overload protection system can ensure long-term operation in the worst hard rock crushing applications, with a low failure rate.

9. The perfect combination of the crushing cavity shape, stroke and crushing speed of the lamination principle; the cavity shape changes from extra fine to extra thick to meet various application conditions; compared with the cone with the same diameter at the large end of the moving cone, the amount of bankruptcy is higher, The grain shape is better.

Figure 11: Various cavity types adjustable

Through the above site cases and product introductions, I believe everyone has some understanding of the performance characteristics of single-cylinder cone crusher. If you need to know other products, you can call our service phone. The ore crushing equipment, crushing screening conveying equipment, milling and beneficiation equipment produced by our company are all at a high level of similar products, and have a certain reputation in the domestic and foreign markets. Exported to many countries and regions, customers are welcome to consult and purchase!

This article was originally published on the website of Shanghai Hengyuan Metallurgical Equipment Co., Ltd. at 18:53 on the evening of June 20, 2020. The company has the right to interpret the crusher model specifications involved in this article; secondly, if you need to reprint and copy this article, please Note the source of the article: https://www.shhyyj.com, our company reserves the right to legally appeal the original intellectual property rights of this article.