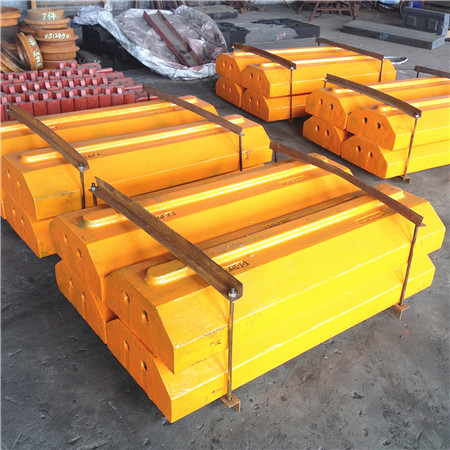

Product Name: Impact Crusher Accessories

Commonly used aliases: counter-attack hammer, high-chrome hammer, composite hammer

Main material: High chromium Cr26, Cr30, high chromium alloy, composite steel, etc.

Production process: V method, lost foam, water glass sand casting, water glass sand casting, 1000 cubic meters heat treatment pool.

Applicable materials: coal gangue, river pebble, granite, basalt, iron ore, limestone, quartz, etc.

Applications: Sand and gravel yard, mining, coal mining, concrete mixing plant, dry mortar, power plant desulfurization, quartz sand, etc.

product description:

Counter-attacking hammers are mainly used in mining equipment impact crushers, which are widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industries. The plate hammer is the wearing part of the impact crusher and is an important part of the counter-attack; the most consumable part of the counter-attack production is the plate hammer, and in the screen production, the traditional process is very easy to cause the appearance of the product to be deformed, not only Correction is difficult and will increase working hours. The plate hammer is an important accessory for the impact crusher. It is a consumable part and needs to be replaced regularly. The wearing parts of the impact crusher include a plate hammer, a counterattack block, a counterattack plate, a lining plate, a square steel, and a pressing block. The fittings are all cast from high-manganese steel, high-chromium, wear-resistant alloy steel and other wear-resistant materials. The hammer has many shapes. It has a long strip, a T-shaped shape, and is generally elongated. The hammer is a common type of impact crusher, which has good toughness and good deformation hardening ability. The material is made of Cr26, Cr26Mo, Cr20, Cr28Mo or special ingredients according to working conditions. Shanghai Hengyuan counter-attacks the hammer to work fine and product innovation, and has the absolute quality advantage compared with the peer products.

High chrome plate hammer:

In view of the working conditions and structural characteristics of the large impact crusher, Hengyuan·China has developed an ultra-high chromium cast iron hammer with high comprehensive wear resistance, and its service life is 1-2 times that of ordinary high manganese steel. Compared with similar products, the semi-solid eutectic high-chromium plate hammer produced by Shanghai Hengyuan has the advantages of high safety, strong wear resistance and high cost performance.

Composite plate hammer

Produced by inlaid wear-resistant alloy technology. In order to lift away its wear resistance, Shanghai Hengyuan is equipped with some ultra-high hardness cemented carbide blocks in the effective wear position of the plate hammer. High wear resistance and resistance to extremely harsh abrasive wear.

Alloy counter block

The alloy counter-attack block uses the chain rail material of the tank armored vehicle, which has good toughness and hardness, and the service life is 1-3 times higher than that of the original high-manganese steel, and the material breaking rate can be increased, and the life of the frame can be extended.

Counterattack

The counter-breaking liner is generally cast from high-manganese steel. The shape of the impact crusher liner is many, mainly in the form of a broken line and an arc. The line-shaped counter-attack surface enables the material at each point of the counterattack to be impacted in an approximately vertical direction, so that the best crushing effect can be obtained. The arc-shaped counter-attack surface enables the block to bounce off the counter-attack plate, forming a severe impact crushing zone in the center of the circle to increase the free impact crushing effect of the material.

Shanghai Hengyuan advises customers to choose a quality manufacturer when they choose to counter the hammer. This can greatly reduce the cost of high-chromium alloy plate hammers, and also save time in replacing the hammers and improve production efficiency.

Quality assurance

Every step of casting production has strict control procedures. Before leaving the factory, it must pass the quality inspection of quality inspection department to ensure the quality of each manufactured product;

Cost-effective

The use of high manganese steel composite jaws doubles the production efficiency of the crusher, reduces the investment cost of casting wear, and reduces the downtime caused by frequent replacement of parts, greatly improving the return on investment;

Technical guarantee

With Hengyuan·China's crusher tooth plate, it can be configured according to customers' individual requirements. The product undergoes scientific and strict smelting, casting and heat treatment processes, in addition to greatly improving wear resistance, it can also improve the aesthetics of broken materials;

Wide range of applications

Widely used in metallurgy, chemical, building materials, electric power, transportation and other industrial sectors, used for coarse, medium and fine crushing of various ores and rocks.

Crusher parts offer is more complicated, so you need to buy counter-attacking hammer accessories customers, please call Shanghai Hengyuan crusher sales hotline: +86-21-33781259 to get the latest offer, you can also choose the field inspection method, buy custom counter-breaking accessories to get more Good buying experience, thank you.