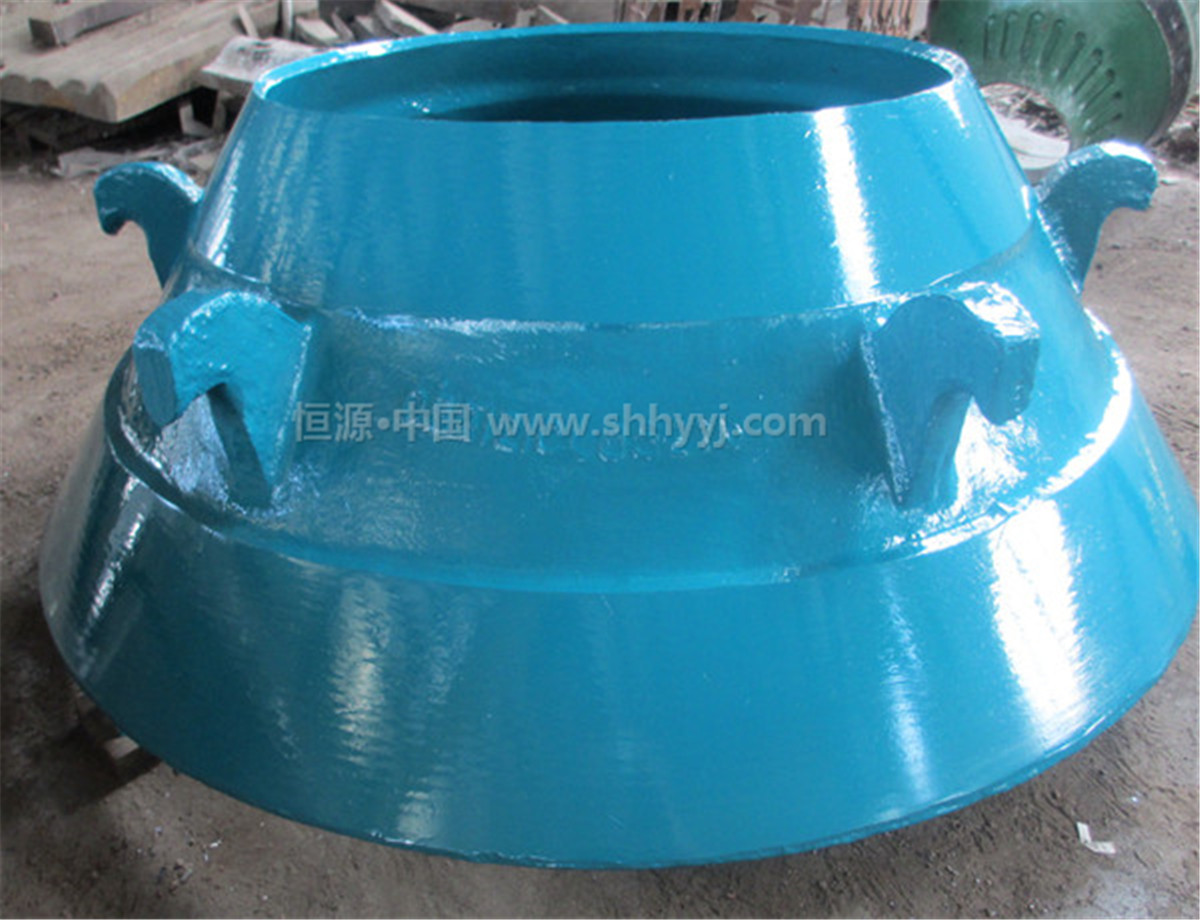

Product Name: Cone crusher rolling wall

Commonly used aliases: rolling wall, conical lining, cone crusher lining, cone crusher lining, static cone, fixed cone, crushing plate, slab wall, broken wall, fixed cone lining rolling wall, broken Wall, moving cone lining, fixed cone lining, conical broken fitting

Main materials: manganese chromium alloy (Mn13Cr2, Mn18Cr2), new composite materials, new composite materials, modified high manganese steel, new high manganese steel, ultra high manganese steel, super high manganese steel, metamorphic high manganese steel Mn13Cr2, Mn18Cr2

Casting process: V method, water glass sand casting, 1000 cubic meters heat treatment pool, etc.

Applicable materials: river pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc.

Applications: sand and gravel yard, mining, coal mining, concrete mixing plant, dry mortar, power plant desulfurization, quartz sand, etc.

Rolling wall product introduction

Cone crusher is widely used in metallurgy, construction, mining and other industries, and can be used as secondary crushing or third-stage and fourth-stage crushing. Hydraulic cone crusher, compound cone crusher, spring cone crusher, various consumable parts are collectively referred to as cone crusher parts. The structure of cone crusher mainly includes frame, horizontal axis, moving cone, balance wheel, eccentric sleeve, upper rolling wall (fixed cone lining), lower broken wall (moving cone lining), fluid coupling, lubrication The system, hydraulic system, control system and other parts are composed, among which the broken wall rolling wall is the most common wear-resistant fitting. The rolling wall is mainly used for various cone crushers, one of the main components of the cone crusher, also known as the fixed cone. Widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industries. Forged with a new composite material, it has the characteristics of super wear resistance and high cost performance. The material is Mn13, Mn13Cr2, Mn18Cr2 (ie ultra-high manganese) or special ingredients according to working conditions.

Importance of rolling wall in cone crusher

When the cone crusher is working, the surface of the broken wall is close to and sometimes leaves the surface of the rolling wall, so that the material is continuously crushed, impacted and bent and broken in the annular crushing cavity composed of the upper and lower broken walls. Rolling wall is the most consumable part of the cone machine, and it is an important part. Shanghai Hengyuan has the best condition according to the different formula ratio and process improvement, which meets the performance and efficiency requirements.

Rolling wall material classification

Manganese 13 (Mn13) rolling wall broken wall

Mn13 has high tensile strength, ductility and toughness, and is non-magnetic. Even if the part is worn to a very thin thickness, it can withstand large impact loads without cracking. It can be used to cast various impact-resistant wear parts.

Manganese 13 chromium 2 (Mn13Cr2) rolling wall broken wall

The use of Mn13Cr2 material, that is, while reducing the C and Mn content of the traditional high manganese steel, adding Cr element, make up for the defect of the traditional high manganese steel toughness, and effectively extend the service life of the wear parts.

Manganese 18 (Mn18) rolling wall broken wall

Casting wear-resistant manganese steel is a standard type of Mn18 high manganese steel rolled wall, containing manganese and high carbon content; the as-cast microstructure of steel is austenite and carbide, water tough treatment at 1050 ° C, most of the carbide Solid solution in austenite.

Manganese 18 chromium 2 (Mn18Cr2) rolled wall broken wall

In order to improve the performance of the crusher wall, many alloying, microalloying, carbon and manganese content adjustment and precipitation strengthening treatment have been carried out. The new micro-alloy rolling wall and broken wall developed by the company are higher than similar products. % does not wait. It has been applied in production practice and has been recognized by the majority of users.

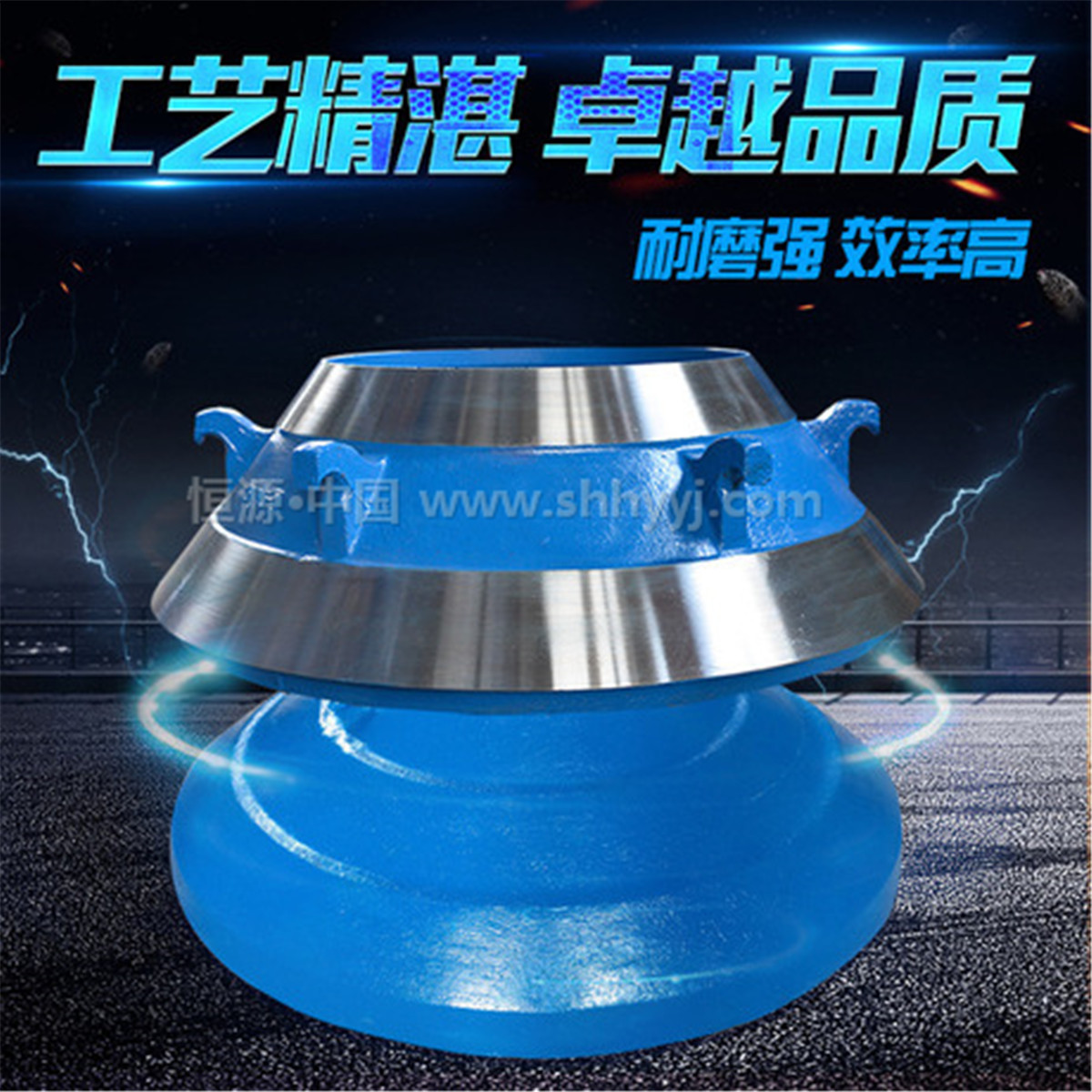

Quality assurance

Every step of rolling wall production has strict control procedures. Before leaving the factory, it must pass quality inspection of quality inspection department to ensure the quality of each manufactured product;

Cost-effective

The rolling wall and broken wall produced by our company can increase the production efficiency of the crusher, reduce the investment cost of casting wear, and reduce the stoppage loss caused by frequent replacement of parts, greatly improving the return on investment;

Technical guarantee

With Hengyuan·China's rolling wall, it can be configured according to customers' individual requirements. The products undergo scientific and strict smelting, casting and heat treatment processes, in addition to greatly improving wear resistance, it can also improve the granular shape of broken materials;

Wide range of applications

Widely used in metallurgy, chemical, building materials, electric power, transportation and other industrial sectors, used for coarse, medium and fine crushing of various ores and rocks.

The price of the rolling wall fittings is determined according to the model of the cone crusher. Therefore, customers who need to buy the rolling wall and broken wall fittings, please call the Shanghai Hengyuan crusher sales hotline: +86-21-33781259 to get the latest offer, or you can choose the field inspection method. , buy a custom rolled wall to get a better buying experience, thank you.