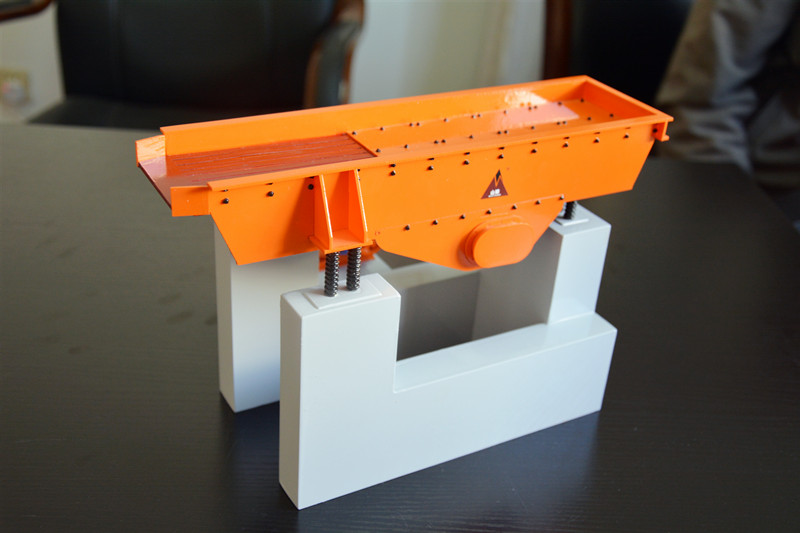

Introduction to vibrating feeder:

The ZSW series vibrating feeder produced by Phoenix is a new type of vibrating feeder designed for evenly conveying large pieces of material before crushing the coarse crusher in the screening. The vibrating feeder adopts the structural characteristics of the double eccentric shaft exciter to ensure that the equipment can withstand the impact of falling of large materials and has a large feeding capacity. In the production process, the block and granular materials can be uniformly, regularly and continuously fed from the storage bin to the receiving device, thereby preventing the receiving device from colliding due to uneven feeding, and prolonging the device. Service life.

Vibration feeder principle:

ZSW and GZD series vibrating feeders are composed of feed trough body, vibration exciter, spring bearing and transmission. The vibration source of the tank vibration feeding is the vibration exciter. The vibration exciter is composed of two eccentric shafts (main and passive) and a gear pair. The motor drives the driving shaft through the V-belt, and the gear on the driving shaft meshes with the passive shaft. Rotating, the main and passive shafts rotate at the same time, so that the tank body vibrates, so that the material continuously flows to achieve the purpose of conveying materials.

Vibration feeder performance characteristics:

In this series of feeders, since the strips with adjustable slits are arranged on the feeding surface near the discharge end, the materials in the material can be separated from the dirt and fine-grained materials at the same time. The crusher functions more effectively; the series of feeders adopts the vibrator and frame ring groove rivet joint structure manufactured by the American branch. It also uses guard plates and rods made of manganese steel, which has strong structure, high strength, impact resistance and wear resistance.

Vibrating feeder parameters:

|

Model

|

Groove size

(mm*mm)

|

Maximum

feed (mm)

|

Processing

capacity

(t/h)

|

Eccentric

shaft speed(r/min)

|

Motor

Power

(kw)

|

Weight

(without

motor)(t)

|

Dimensions

(mm*mm*mm)

|

|

GZD 300×90

|

3000×900

|

450

|

40-100

|

----

|

2××2.2

|

2.64

|

3050×1430×1550

|

|

GZD 370×100

|

3700×1000

|

500

|

100-150

|

----

|

2×3.7

|

3.69

|

4250×1874×1130

|

|

GZD 430×120

|

4300×1200

|

650

|

200-400

|

----

|

2×5.5

|

4.2

|

4955×2206×1120

|

|

ZSW-380×96

|

3800×960

|

500

|

100-160

|

500-714

|

11

|

4.2

|

3882×1684×1340

|

|

ZSW-490×110

|

4900×1100

|

630

|

120-280

|

500-800

|

15

|

5.5

|

4957×2400×2150

|

|

ZSW-590×110

|

5900×1100

|

630

|

200-350

|

750

|

22

|

6.1

|

6000×2500×2150

|

|

ZSW-600×130

|

6000×1300

|

750

|

400-560

|

500-800

|

30

|

7.8

|

6082×2580×2083

|

|

ZSW-600×150

|

6000×1500

|

800

|

460-575

|

500-800

|

30

|

8.7

|

6086×2662×2186

|

|

ZSW-600×180

|

6000×1800

|

800

|

600-800

|

500-800

|

37

|

11.8

|

6310×3262×2230

|

Note: Parameters are subject to change without prior notice, please contact us.

Vibrating feeder factory picture:

Vibrating feeder delivery pictures:

Vibrating feeder model:

Vibrating feeder site picture:

Vibrating Feeder Video:

Vibration feeder price:

The price is determined by the model purchased by the customer, so please call the customer to request it.

Vibration feeder purchase Phone: +86-021-33781259 Email:info@shhyyj.com