Introduction to the rotary crusher:

In the face of the peak period of China's high-speed railway construction, the demand for the rotary crusher market is extremely strong. For high-speed railway construction, the requirements for gravel aggregate and concrete aggregate are relatively high, and at least ten large-scale enterprises with such production capacity in the rotary crusher industry that meet the demand are at least ten. The rotary crusher has been widely installed in the construction of highways and high-speed railways in various provinces and cities across the country, and is an indispensable equipment for national infrastructure construction. For the basalt crushing, the stone crushed by the rotary crusher can reduce the stone needle-like content to about 4% after being crushed by the impact crusher. It is an ideal composite crusher in the sandstone aggregate production process. device.

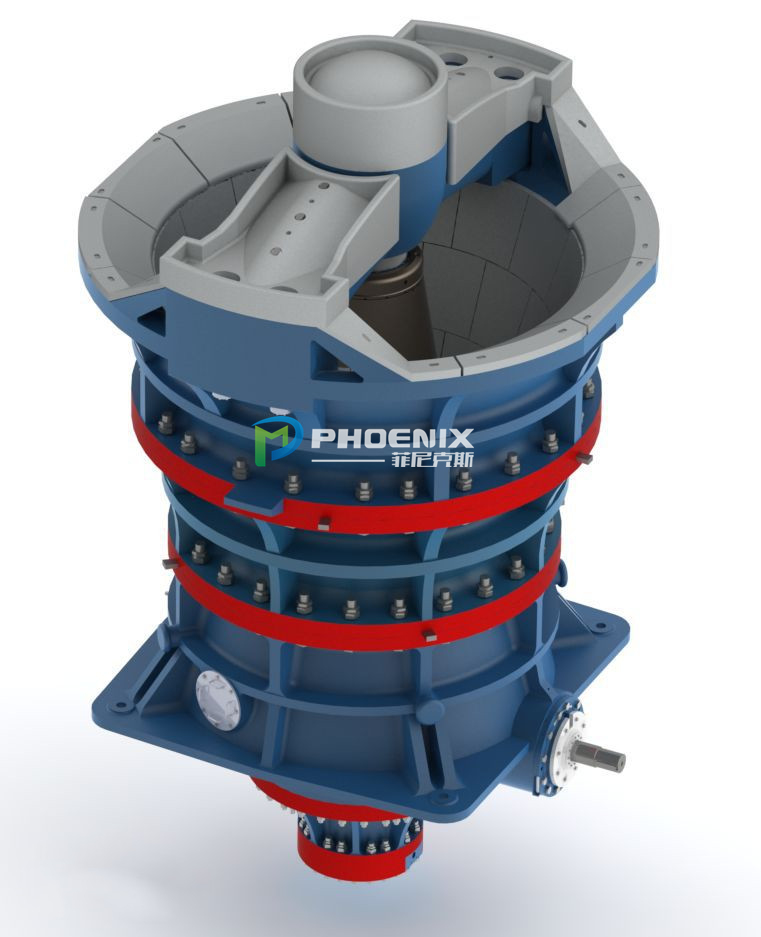

The principle of the rotary crusher:

The rotary crusher is a large-scale crushing machine that uses crushing motion of the crushing cone in the cone cavity of the casing to cause extrusion, splitting and bending of the material, and coarse crushing of ore or rock of various hardnesses. The upper end of the main shaft equipped with the crushing cone is supported in the bushing in the middle of the beam, and the lower end is placed in the eccentric hole of the bushing. The rotary crusher is a vertical composite crusher, also known as a composite crusher, which is a machine for crushing production lines and sand production lines. The upper end of the main shaft equipped with the crushing cone is supported in the bushing in the middle of the beam, and the lower end is placed in the eccentric hole of the bushing. When the sleeve rotates, the crushing cone rotates around the center line of the machine, and its crushing action is continuous, so the working efficiency is higher than that of the jaw crusher. By the early 1970s, large gyratory crushers were able to process 5,000 tons of material per hour, with a maximum feed diameter of up to 2000 mm. The rotary crusher realizes the adjustment of the discharge opening and the overload insurance in two ways: First, the mechanical method is adopted, and the upper end of the main shaft has an adjusting nut, and the rotating adjusting nut can be lowered or raised, so that the discharge opening is followed. Larger or smaller, when overloaded, the insurance pin on the drive pulley is cut to achieve insurance; the second is a hydraulic hydraulic gyratory crusher whose main shaft is located on the plunger in the hydraulic cylinder, changing the plunger The volume of the hydraulic oil can change the upper and lower positions of the crushing cone, thereby changing the size of the discharge opening. When overloaded, the downward pressure of the main shaft increases, forcing the hydraulic oil under the plunger to enter the accumulator in the hydraulic transmission system, causing the crushing cone to descend to increase the discharge opening and discharge the non-material entering the crushing chamber. Broken objects (iron, wood, etc.) to achieve insurance.

Rotary Crusher Features:

1. The structure is simple and reasonable, and the running cost is low. Using the stone stone principle, the wear is small.

2. High breaking rate and energy saving.

3, with fine crushing, coarse grinding function.

4. It is affected by the moisture content of the material and the moisture content can reach 8%.

5, more working noise is less than 75 decibels (db level), less dust pollution.

6, suitable for crushing medium hard and extra hard materials.

7, the product into a cube, bulk density, iron pollution is minimal.

8. The impeller self-lining wear is small and easy to maintain.

Rotary Crusher parameters:

|

Model |

Feed port size

(mm) |

Discharge port adjustment range

(mm) |

Processing capacity

(t/h) |

Motor Power

(kw) |

|

HYX810 |

1100 |

140-170 |

1120-1880 |

355 |

|

HYX830 |

1300 |

140-170 |

1560-2370 |

355 |

|

HYX1040 |

1400 |

160-210 |

2081-3015 |

450 |

|

HYX1050 |

1500 |

160-210 |

2350-3380 |

450 |

|

HYX1150 |

1500 |

175-220 |

3805-4930 |

800 |

|

HYX1450 |

1500 |

200-250 |

5315-6813 |

1100 |

Note: Parameters are subject to change without prior notice, please contact us.

Rotary crusher installation method:

1. The equipment should be installed at the level of the concrete foundation and fixed with the anchor.

2, the installation should pay attention to the main body and vertical level.

3. Check whether the bolts are loose after installation, and strengthen the door of the host country and tighten the requirements.

4. Configure the power cord and power control switch according to the device.

5, inspection is completed, empty load test, test, production can be normal.

Troubleshooting and troubleshooting

1. Fault phenomenon: fine granularity;

Reason: more hammers;

Solution: Remove one or two layers of hammer.

2, failure phenomenon: coarse grain size;

Cause: The belt is loose or the speed is low;

Solution: Tighten the belt and check if the voltage is 380V.

3, failure phenomenon: the broken body swing;

Cause: The centrifugal force of the rotor is not balanced;

Solution: Replace the new hammer or adjust the weight of the pusher.

Rotary Crusher Video:

Rotary Crusher Price:

The price is determined by the customer's model, so please call us.

Rotary Crusher Purchase Phone: +86-021-33781259 Email:info@shhyyj.com